FAQ

Industrial RO Plant

Industrial RO plant is highly used in the food and beverage industry, where water treatment is essential for quality and consistency. RO technology is used to purify water for drinking and household purposes. Patients undergoing any urinary/kidney treatment, especially dialysis, require RO water to complete the session. RO water is low in mineral content, and It is used in car washing to prevent water spots on the vehicle.

Cost depends on many factors like water TDS and minerals dissolved in water at your location, the production capacity of the Commercial RO Plant, the place of plant setup, cost of transportation, water Source feed and its chemistry, the type of water packaging plant, and productions (Such as bottle, jar, pouches, etc.). We are one of the best-rated commercial RO plant / Industrial RO Plant consultants.

Installing Industrial RO is a multi-step task. It includes requirement analysis to implementation and after-sale and support services. To know more about our services, please contact.

Industry Water Solutions provides a wide range of wastewater treatment plants with different capacities. The installation process is awe-inspiring and timely. We respect our valued customers' needs and requirements and provide them with treatment plants on time with the pre-quality checkup. Our employees are committed to their assigned work. Sales and Service department work hard to make you understand regarding your queries.

At Industry Water Solutions, you'll find varieties of RO Water Plants available in the following flow ranges, Big Reverse Osmosis Plant (RO Capacity 10000 LPH), Automatic Reverse Osmosis Plant (RO Capacity 500 LPH), Semi-Automatic Reverse Osmosis Plant (RO Capacity 250 LPH), Institutional Reverse Osmosis Plant (RO Capacity 1000 LPH), Stainless Steel Reverse Osmosis Plant (RO Capacity 1000 LPH), and many more.

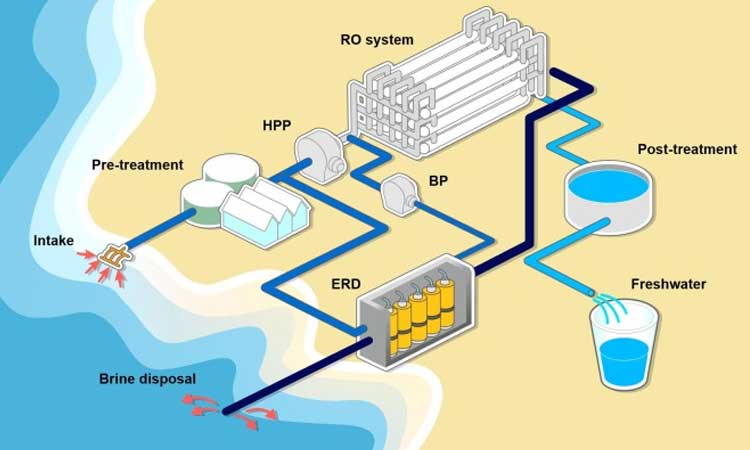

Reverse osmosis uses a membrane that filters down to the molecular level, removing dissolved chemicals and salts that a regular filter cannot remove. Traditional water filters physically screen dirt and sediment particles from the water to about one micron but do not remove dissolved chemicals. Using a RO system will reduce all these contaminants significantly, protecting your body from absorbing them and potentially refreshing your body.

A water treatment plant's service and maintenance plan is a simple process to ensure that the water treatment plant operates at the desired performance. Industry Water Solutions offers maintenance and services to ensure that the water treatment solutions function at the best performance. Membrane exchange is may required every 3 to 5 years, depending on the other factors.

We set up the plant for water purification of flow rates above 100 LPH. We use the finest standard of fibre Reinforced Plastic as well as stainless steel to build the units. The operations performed by the plants are manual as well as fully automatic. To know the water treatment plant price or more about us, please contact us for Free Quotation.

Commercial RO water purifiers give you various benefits, such as reducing the use of plastic bottles, cost-effective service, better taste of water. Water treatment industries have adopted reverse osmosis as one of the water purification techniques. Industries like mechanical, chemical, pharmaceutical, food and beverage, plastics, automotive, oil/gas, and paper manufacturing utilize reverse osmosis systems for pre-boiling water treatment/conditioning.

In RO plants, water from any source is treated by reverse osmosis technology to make it fit for consumption. The reverse Osmosis method uses pressure to purify water. Mineral Water is natural water that does require any purification treatment and adding required added mineral before bottling it up.

Sewage Treatment Plant (STP)

Its work on the principle of Aerobic Treatment with the help of aerobic bacteria is the most conventional and proven method throughout the world. We offered a portable sewage treatment plant, domestic sewage treatment plant, MBBR, and water recycling plant. Using internal mechanisms, a sewage treatment plant breaks down solid waste to produce a cleaner, more environmentally friendly effluent. In the chamber, a pump airs the wastewater and encourages friendly bacteria to condense the organic matter. This process breaks down and purifies the wastewater.

Industry Water Solutions is a reputed name in the field of several types of Water Treatment Plants. We offer plants of various capacities to cater to the needs of different clients requirements. The plants, especially the sewage treatment plant in India, use state-of-the-art technology to remove physical and biological impurities of water coming from kitchens, washrooms, toilets, and washing machines. We treat water sufficiently pure to be used for gardening or flushing. The water is safe for water bodies or underground water recharging. Being a reputable sewage treatment plant manufacturer, IWS aims at providing excellent sewage water treatment systems that are hassle-free, easy to use, and efficient in execution. Each product is factory-tested and guarantees good performance. Plug and play installation, long-lasting service, and smooth working are the distinct features. You find many variants of the water treatment plant. Each one has some different features and usage.

Sewage is the waste generated from residential, institutional, commercial and industrial establishments. STP plant treats the sewage to make it fit for safe disposal, agricultural use, domestic use in toilets, etc. Sewage usually contains a high quantity of organic and inorganic wastes. It is essential to treat sewage before it enters into any water body. Suppose sewage is allowed to enter the water sources without treatment. In that case, it will contaminate them, so it is essential to treat sewage properly before letting it into rivers or any other water sources.

Sewage can be treated by designing a sewage treatment plant (STP) that involves primary/preliminary, secondary and tertiary stages. Primary treatment: Sewage water is first allowed to pass through screens or grit chambers where large solids are removed. This step is followed by aeration/mixing in a tank and primary sedimentation where suspended solids settle down. Secondary or biological treatment: This stage converts organic matter in sewage into stable forms through biological activities, resulting in secondary sedimentation. Common approaches are trickling filters and the activated sludge method. Tertiary treatment: The effluent then undergoes tertiary treatment/disinfection by incorporation of UV radiation or chlorination. Other methods such as sand filters and reverse osmosis may also be used instead for this stage of treatment, depending upon the nature of the sewage and the effluent from secondary treatment.

ETP may be a system that removes toxic and non-toxic material from water and makes it usable for various purposes. STP unit removes contaminants from municipal wastewater or household sewage. ETP is employed in industrial areas, whereas STP cleanses household water. Pharmaceuticals, chemicals, and leather industries generally use Effluent Plants, where Sewage plants are utilized in residential areas like societies and apartments.

Sewage treatment plants for residential societies offer the latest technology with MBBR, MBR, and SBR for Hotels and resorts capacity from 10 kld to 10 mld sewage treatment plants for residential societies are widely sought after installations, by which harmful contaminants are removed from sewage/ wastewater. Such liquid or solids are rightly considered safe for disposal into the environment or even for re-use. For residential complexes, we are a prominent sewage treatment plant manufacturer with abounding expertise, and we provide treatment installations in the form of opened plants or closed underground treatment frameworks.

The SBR, MBR and MBBR are used as sewerage treatment plants. To separate the contaminants from the wastewater is the sole aim of each SBR or MBBR sewerage treatment plant in India. These all have various purposes, and they have their method to wash the wastewater.

Effluent Treatment Plant (ETP)

An effluent treatment plant cleans industrial effluents, contaminated water from rivers and lakes, and reuses for additional purposes. Such gushing treatment ensures that any contaminant will be discharged from the water, making it reusable. Along such lines, water is reutilized and sustained. It is mostly used in pharmaceuticals, textiles, tanneries, and chemicals where there is a chance of extreme water contamination. Nevertheless, how this treatment will be applied may vary from industry to industry. Such treatment plants ensure that the contaminated and polluted water from industries gets treated and becomes reusable before being released to nature. Without this treatment, it won’t be possible for humans to get clean, usable water for household chores.

Industry Water Solutions is the big and one of the fastest-growing names in the industry of Effluent Treatment Plant Manufacturers. Our world’s best cutting edge latest technology and research team ensure you the best ETP plant and best effluent treatment system towards saving the mother earth from water pollution problems. Our best mechanism covers the effluent treatment to generate zero discharge while treating your industrial waste before discharging it into the environment.

There are about 36 to 38 parameters that need to be analysed to assess the wastewater quality. These are called water quality Parameters and indicate the presence of pollutants in the water. These parameters are listed in the State/Federal or Central pollution control board as a standard water/wastewater treatment handbook.

The characteristic of wastewater must be taken into consideration in terms of physical, chemical and biological factors. The size of the effluent treatment plant, i.e. ETP, depends on its flow (measured in m3 / day. The wastewater flow should be estimated correctly, considering all possible reasons. Otherwise, they will also affect hydraulic computations, channels and pipes if there is a need to construct an equalization pond due to large temporary flow (e.g. rainfall, etc.) to maintain constant flow downstream treatment process. Equalization ponds also help to reduce the toxicity of wastewater. Physical Characteristics of Wastewater include PH, Colour, odour, temperature. Suspended solids, grease, oil indicate highly polluted wastewater with very low turbidity. The presence of these matters shows the need for pre-treatment before releasing to the environment. Temperature is also a significant factor because the higher the temperature higher the reaction rate.