Manufacturers are Likely to Use Demineralized Water for Making the Watch

Wristwatches that had microchip technology with quartz crystals have become trendy nowadays. In this article, we elaborate the manufacturing process of watches. Next, we will discuss a unique use of a DM water plant in manufacturing watches in the industry. Also, why the manufacturers do not use regular water described in the article.

Globally, the preference for high-quality, premium watches made with steel, bi-metallics, and precious metals are on-demand as it attracts consumers. Wearing these types of watches is perceived as a status symbol. People are interested in using quality products made with highly advanced production technologies, materials, and methods. The use of accessories to improve one's looks is a common fashion trend. This factor is, therefore, contributing to the growth of the luxury watch market.

Condensation can be the biggest clue to the existence of water inside a watch's case. If the crystal on the watch has droplets of water inside, the watch will lose its accuracy. It can be a problem since the water can make the metal elements get rusty. If the water is saltwater, that could prove to be even worse, as the watches are susceptible, and other particles can corrode the metal and irreparably damage the watch.

Don't be the leak in our global flow.- The Dharma Trails.

Using demineralized Water to clean the watches can be a good solution for watch manufacturers as it does not contain harmful chemicals. Demineralized Water is the water that has its mineral ions removed. Mineral ions such as cations of sodium, calcium, iron, copper, and anions. Deionization is a physical process that uses specially manufactured ion-exchange resins.

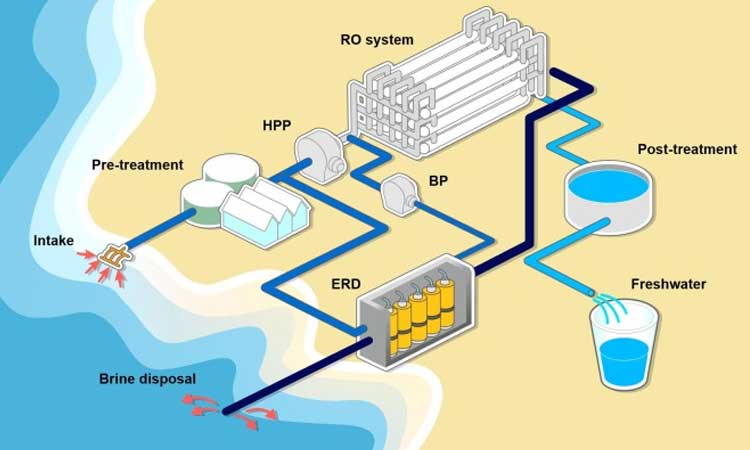

DM (demineralized) water plants are systems used to carry out industrial water treatment. The DM plant removes dissolved solids or minerals from process streams and feeds water. These plants remove minerals using any one of the following procedures:

- Deionisation

- Distillation

- Electrodialysis

- Membrane filtration (nanofiltration or reverse osmosis)

In conclusion, we suggest that using DM water in making watches is the best option. Normal water can leave stains or water droplets on the dial after washing it. As we all know, premium watches are costly because of microchips (made of silicon) technology inside them. The watches are made with gallium arsenide, modern materials, plastics, and alloy metals. Making elite watches is very expensive. That is why using normal water is not the first choice for manufacturers. They are likely to use Demineralized water for cleaning it or for making waterproof watches.

Comments

For boiler applications' we required extra pure water with a TDS of < 1.0 mg/l to safeguards the boiler tubes & Turbine blades. Through the demineralization process, we are removing all ion's present in the water with the help of Cationic & anionic resins.

Human use of water results in contamination. and water from any combination of domestic, industrial, commercial or agricultural activities surface runoff or stormwater. Therefore wastewater is a byproduct Of domestic, industrial, commercial or agricultural activities.

In D.M Plant, process water is allowed to pass through pressurized bed filter, carbon bed filter, cation exchanger, anion exchanger, de-gasifier and mixed bed exchanger.