Needs of Industrial RO Plants and its installation guidelines for food and beverage industry

Water is the main component in the food and beverage industry that must be free from undesirable impurities, including unwanted tastes, smells, and colours. This article gives you information about the usage of RO plants in the food and beverage industry and the installation guideline. The importance of RO based wastewater treatment plants in the current scenario, Structure of treating wastewater. Read this article until the end if you want to know everything done while installing the Reverse Osmosis Plant in the food and beverage industry. Releasing clean water back into nature or using it for agricultural purposes for soil irrigation contributes to protecting our planet's biodiversity and, therefore, future generations.

The food processing company utilizes RO treated water purposes are: Food production, Food Cleaning, and Recycling water. Baby milk production demands high purity water. Dairies and meat processing facilities also have many requirements for cleanliness water, including hygiene & food security contemplations, plus regular wash down. The beverage industry uses the RO water plant to produce beer, wine, spirits, soft drinks, and juices. With the increase in population comes a rise in water consumption and pollution.

The food and beverage industries are constantly facing problems regarding water supply and water quality. During certain seasons, the water supply becomes unstable due to droughts, or torrent rain and heavy flooding can cause issues with the overall quality of the water supply and contamination of the aquifer. One of the significant challenges in supplying water of the necessary quality for reuse is selecting an appropriate treatment system. Here are some of the reasons why water quality matters in the proper functioning of the food and beverage industries.

- 1. Uncontaminated Foods and Drinks- Water quality directly dictates the overall quality of the manufactured foods and drinks, which is, by far, the biggest reason why the industry should adhere to set standards concerning water purity, or they might face legal consequences.

- 2. Cleaning and Sterilization of Equipment- Using purified treated water inside an unsterilized environment is unnecessary. Properly treated and sterilized water should use when washing the packaging equipment, vehicles, and storage facilities.

- 3. Reduce Downtime - It becomes crucial to use recycled water that needs to be appropriately treated and purified to sustain uninterrupted operations.

Water helps human beings to complete their life. We can use water resources for the following purposes-drinking and the disposal of wastes, as a source of providing food, irrigation of crops, driving machinery or generating power, and for recreation purposes.

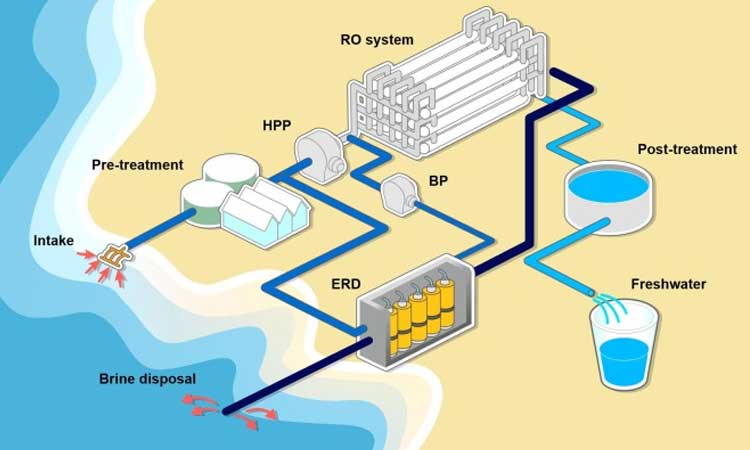

RO is used to concentrate fruits and vegetable juices, pre-concentration of milk, and dealcoholizing alcoholic beverages. The beverage industries (the industry that makes cans and bottles) used quality water to spray-cool heated bottles. With the onsite treatment plant expansion, enterprises can use spray water again for its original purpose. To optimize these industrial RO systems and improve their productivity, Industry Water Solutions has numerous options available for pretreatment and post-treatment, including media filtration, UV disinfection, and ultra-purification. We also offer Effluent Treatment Plant (ETP), Sewage Treatment Plant (STP), DM Water Plant, Water Softener. You can rely on us to ensure the smooth operation of installation. The first step involves the quality checking of the water, which is known as TDS. Then, we design the RO membrane according to the report. We further provide quotations consisting of all related and vital information regarding wastewater treatment plants. After completing all the above processes, our skilled engineers install the treatment plants at the preferred locations.

Reverse osmosis is a valuable technology that allows manufacturers in the industry to generate high purity water. Enterprises are expected to create significant opportunities for water-related investments in the food and beverage industry. The market will remain highly positive towards product innovations, technological upgrades, sustainable practices, and water-saving solutions. With the water footprint of food and beverage products set to become an industry standard, all services related to water conservation, water reuse and recycling technologies, and generating renewable energy from wastewater will be highly preferred. Increasing water scarcity worldwide will make facing the challenges of implementing water reuse systems in the food industry unavoidable. There is excellent potential for water reuse in food manufacturing. Current legislation acknowledges the use of recycled/reconditioned water when product safety is not compromised. Following is a risk assessment protocol based on Hazard analysis and critical control points (HACCP) that will ensure that microbiological, chemical, and physical hazards consider the design of water reuse applications.

Comments

The water obtained through RO is supposed to be dead water (i.e., neutral water) as it removes all minerals – good and evil. However, dead water is acidic since its pH slides below seven without alkaline minerals like calcium and magnesium. As a result, it generates water that is neither harmful nor helpful.

Introducing RO as an industrial wastewater solution is a greener alternative to using harmful chemicals. The combination of pressure and uniquely designed membrane systems remove harmful products so water can re-enter the water cycle safely or even be reused in production. RO has many benefits, with its substantial environmental factor being just one of them. As society becomes more aware of issues such as water pollution, laws and regulations are expected to become tighter.

Great quality purifiers focus on purifying specific contaminants. Some use carbon to filter out chlorine; some use activated carbon to kill bacteria; some use ultrafiltration to remove viruses like e. coli. Some use the reverse osmosis process to remove all including sediment, minerals, and hundreds of contaminants found in any body of water, including drinking.