Cruise Liners Innovative Water Conservation Management System

Cruise are beautiful creations, outside and inside, with all their paraphernalia done to artistic perfection. Millions of guests set sail on their dream vacations each year on these engineering and artistic marvels. Seawater is available, but people do not drink it as it contains a lot of salt. The cruise industry has to adopt innovative ways to reuse the water because they spend time in the sea. That is why we discuss the wastewater method onboard. The article highlights the prevailing situation by addressing the problems faced by people. We will also try to explain how do cruise liners manage water that is suitable for drinking. We also emphasize the reuse applications adopted by them.

Freshwater ismandatory on cruise ships for drinking, galleys, laundries, high-pressure washing & cleaning purposes. Also required for steam generation, various heating & cooling systems within and outside the machinery spaces, sprinkler, and hyper-mist systems for fire-fighting and recreational purposes. It is particularly important in developing countries where freshwater is limited and best reserved for local communities. Norwegian Cruise Line, a cruise company under its Sail and Sustain Stewardship Program, has been working tirelessly to launch several innovative initiatives to adopt wastewater treatment methods that will reduce the CO2 emissions rate, increase sustainable sourcing, and invest in emerging markets technologies.

Drinking seawater causes rapid dehydration and death. It includes substances such as human waste, food scraps, oils, soaps, and chemicals. Contains water from sinks, showers, bathtubs, toilets, washing machines, and home dishwashers.It is also highly corrosive due to extremely high levels of dissolved salts and chemicals. It will stain, corrode, and eat up all the plumbing, and silver-wares in a heart-bit. Seawater causes pitting corrosion in stainless steel, copper, aluminum, or any other metal, and most kitchen-wares these days are made of stainless steel. But we can make seawater functioning by acquiring proper methods of filtration.

You don’t command wind in the direction it blows, but you command a ship in the direction it sails.- Matshona Dhliwayo

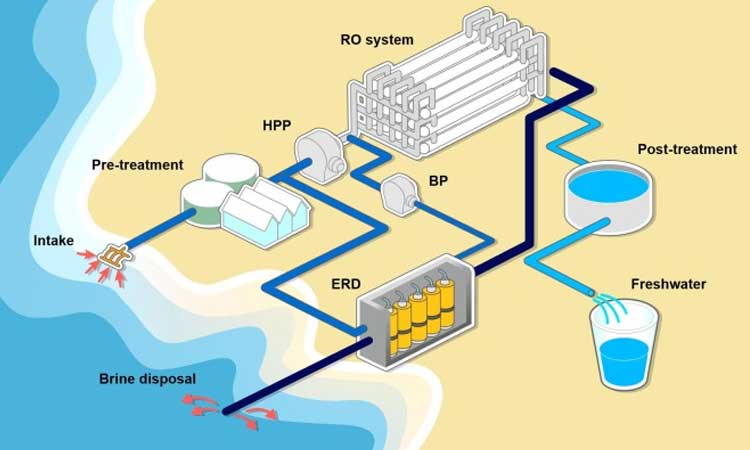

Reverse Osmosis, Evaporators, and Bunkered water can be a solution for cruise liners to provide freshwater to the passengers. RO produces fresh and technical Water from seawater using high-pressure pumps and sophisticated water filters and treatment components. Bunkered Water is potable Water acquired in port for use onboard. Evaporators utilize heat sources such as Exhaust Gas Boilers, Oil Fired Boilers, or Wasted Heat recovered from the main engine's high-temperature cooling system. Increased or upgraded onboard RO plants and additional water meters to measure water consumption is a good step to strategize better on reducing the usage.We deal as a commercial RO plant manufacturer, Sewage treatment plant manufacturers, effluent treatment plant manufacturers. Contact us to discuss your requirements. Feel free to leave your query.

Desalination is an artificial process by which saline water is converted to freshwater. The desalination process usually involves steam evaporation, essentially turning saltwater into distilled water. That water is then mineralized for flavor and chlorinated for extra safety.The metal-organic framework helps in filtering out harmful particles from the water and producing 139.5 liters of clean water for every kilogram of MOF per day. Industry Water Solutions incorporates the latest technology that conforms to the predefined industrial standards and quality. Therefore, you don't have to worry about the quality and services. We are one of the most cost-effective companies committed to preserving water.

To protect the health of passengers and crew, water used for potable purposes onboardships should be provided with sanitary safeguards in a multiple-barrier system. Every ship's wastewater is tested quarterly by a third party. In addition to that, environmental officers onboard conduct weekly water tests to ensure that the industry meets all standards. An operation is known as ballasting, which helps to ensure a trim, stability, and structural integrity. Filling ballast tanks with ocean water helps stabilize ships, providing comfort to guests and crew. As water is discharged or as fuel is consumed, ships take on seawater to assist with stabilization. The environmental impacts of desalination must be weighed against those of expanding use of freshwater sources (e.g. groundwater depletion, diverting surface water flows).

Comments

Cruise ships carry thousands of tonnes of freshwater with them. The systems for loading, producing, storing, and distributing potable water are extensive, and receive constant attention from the Engineering Officers on duty.

For ships serving a US port sanitation practices are controlled by the CDC Vessel Sanitation Program. It sets out, in tremendous detail, all regulations concerning all aspects of sanitation aboard passenger ships under its jurisdiction.

Through the use of desalination or osmosis. water desalination equipment converts seawater to drinking water on board ship, even sailing yachts have them nowadays - no need to carry enough fresh water to last the whole cruise.