The workings of a commercial RO Plant

A commercial RO plant removes all pollutants from water, allowing it to be used for various commercial purposes. You will be surprised after reading the article as it will cover all the information related to Commercial RO Plant. We will also discuss the best manufacturers of Commercial RO Plant in this article.

Commercial reverse osmosis plants found in shopping malls & hospitals are the most cost-effective water treatment methods. It purifies the water by removing impurities such as non-essential metals, acidic salts, and chemicals.

If it can’t be reduced, reused, repaired, rebuilt, refurbished, refinished, resold, recycled, or composted, then it should be restricted, designed or removed from production.- Pete Seeger, Folk Singer & Social Activist

There are three main advantages of the Commercial RO plant, and they are:

- Improves the taste, smell, odor, and appearance of the solution.

- Highly effective purification process.

- Helps in removing pollutants like bacteria, pyrogens, viruses, radioactive contaminants.

Following are the features of the Commercial RO Plant:

- PLC-based controllers

- SS High-Pressure Pipe Assembly

- Cartridge Filter

- Outlet conductivity meter

- Pressure Gauge

- UV Protection Grid

Commercial RO Plants; The working principle:

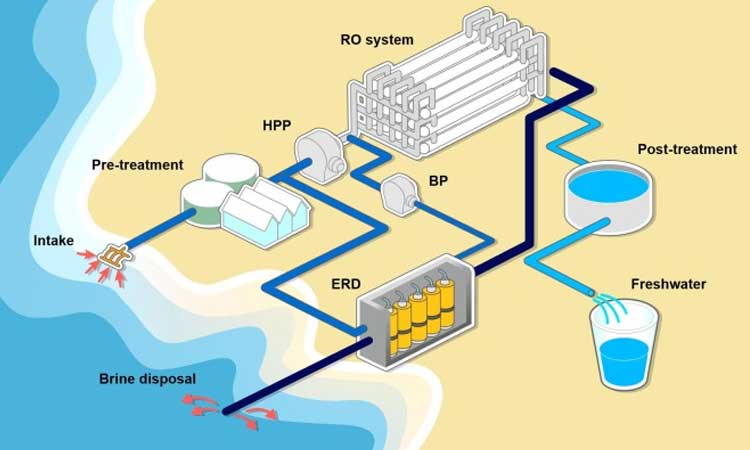

It works on PreTreatment and Post Treatment.

Pre-Treatment (to make the feed water to the RO compatible with the membrane)

- Clarification of water

- Sand filtration

- Water softening for reducing the hardness

- Water is passed through activated carbon filters

- Final removal of suspended particles using cartridge filters

Post-Treatment (chemical addition to adjust water quality)

- Ozonation

- Ultra-violet

- Chlorination Systems

In general, Pre-filtration, Purification, and Post-filtration are the three phases of complete solutions. The fourth and final step of distribution offers convenience. Under-sink purifying/filtration machines produce between 100-165 liters of water sufficient to give drinking water of excellent quality to a yacht's crew, owners, and visitors, or 50-130 liter of water for a family/office.

A. PRE-FILTRATION (aims to protect the purification membrane)

Adsorption and micron filters are used to remove hazardous particles. The chlorine is adsorbed by an activated carbon filter, which removes the odor and taste.

B. PURIFICATION (the purification step)

Uses a partially permeable membrane to separate ions, unwanted molecules and larger particles from drinking water.

C. POST FILTRATION (re-introduces essential minerals)

After purification, the permeate is slightly acidic (depending on the quality of the raw water) and chemically tasteless. The permeate picks up these minerals based on the water pressure and flow rate for creating healthy drinking water.

Best Manufacturers in India of Commercial RO Plant

Industry Water Solutions is established as a design, fabrication, installation, and maintenance, service provider for wastewater treatment. We have years of expertise and are intimately intertwined with its equipment solutions, testing, monitoring, analysis, and recommended corrective actions. Our mission is to make wastewater management systems affordable, sustainable, and energy-efficient to cope with the challenges of population growth, industrial expansion, and climate change.

A remarkable observation is that adverse health effects were obtained in none of these points mentioned above, even on a long timescale. It shows that the technologies for producing clean water from wastewater are available, but not everyone is convinced. Therefore, educational programs and information campaigns must address a good direction for the future to stimulate water recycling.

Comments

The level of treatment depends upon the end use, which can range from cooling, irrigation, industrial processing, drinking water, and high tech electronics applications.

Manufacturing the bottles involves chemicals including phthalates, benzene and toluene. When the water in the bottle is repeatedly heated and cooled, that encourages the chemicals to leach into the water.

Water treatment can be done in many different ways that all try to remove any dispersed or dissolved matter from the pure H2O. The simplest way is to just let the wastewater flow through a large lagoon (volume > 200 days of inflow, e.g. 100 m3 for a family) and you have water that is OK for subsoil irrigation.